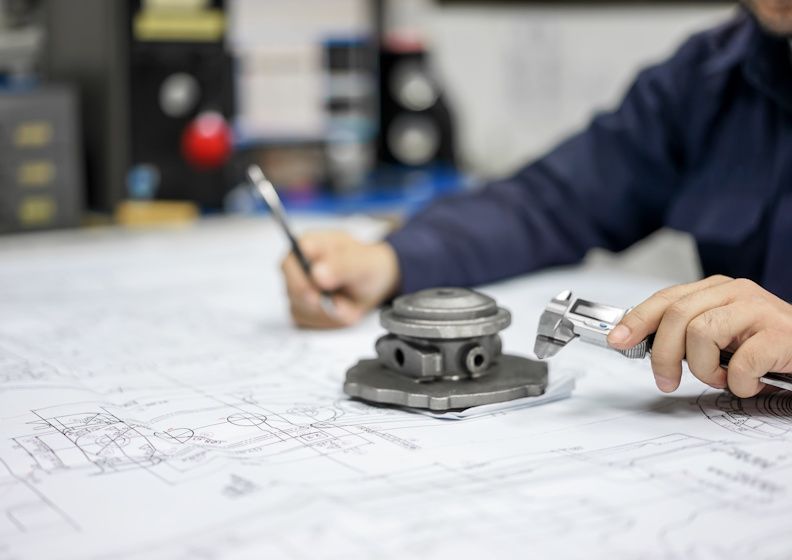

Benefits of Adding CAD Modeling to Your Process

Accurate documentation and exacting design are critical to your process, but it’s also important to “see” a part or structure before you begin building. These are just a couple of the reasons why CAD modeling can be a valuable tool.

Here are some of the main advantages to this technology:

Improved Forecasting and Visualization: 3D CAD modeling allows your process to become even more data driven, with accuracy around planning and materials procurement. You will also gain insights into the variety of “what if” scenarios that could occur during your building phase, allowing you to plan for contingencies.

Faster Time-to-Market: 3D CAD modeling, whether utilized for a smaller part or an entire machine, can allow your company to move faster to meet client requests. Utilizing the parametric design capabilities of modern CAD modeling makes initial decision-making more efficient, but the solution also prevents unexpected delays that can occur with other design approaches.

Reliable Documentation: Utilizing 3D CAD modeling provides you with full documentation of your design process. This allows you to standardize your drafting and detailing elements so that you can use parametric data from your models to automatically fill out Bill of Materials, title blogs and other key information. It also equips you to optimize materials consumption and improve your speed of design.

Inform Stakeholders: Engineers and designers appreciate the ability to see a design in the planning stages, and so do your investors, executives and other stakeholders. Using CAD models allows all team members to easily visualize the end product. This helps to keep your entire team excited about the project by providing a vision for your design.

CAD modeling is a good fit for your process, and Finite Engineering is the CAD modeling expert you want to partner with on your next project. With each step tailored to your needs, Finite Engineering works to help you meet your timeline, budget and client specifications. Contact us to get started.