Finite Element Analysis (FEA) Services

Analyze weaknesses and receive recommendations to optimize your design

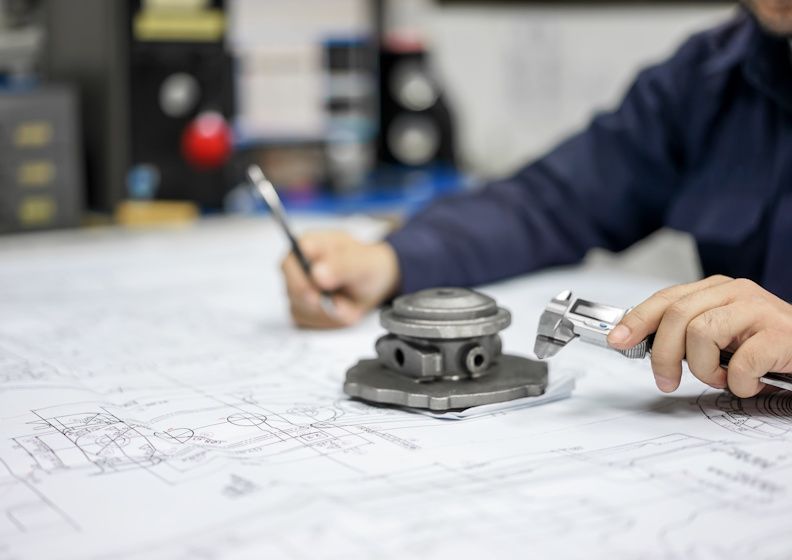

FEA allows for a detailed visualization of where parts bend or deform, and indicates the distribution of stresses and displacements. In addition, FEA is capable of a wide range of simulation options controlling the complexity of both modeling and analysis of any design.

We utilize Abaqus CAE, Solidworks Simulation and Inventor NASTRAN for our Finite Element Analysis services. Our engineers can perform linear, non-linear, vibration, buckling, impact, and more product quality analytics.

Finite Engineering has extensive experience applying targeted experimentation for calibration and validation of finite element simulations. We provide a comprehensive technical report detailing stresses, strains, and deformations. Based on the FEA results, recommendations are made for design optimization.

Achieve Design Optimization and Resolve Analysis Challenges

Finite Element Analysis solves potential problems in engineering and mathematical models. It involves a computer simulation that tests the strength of complicated designs. With FEA, you will visualize how your product or solution will perform under any load, thermal, structural, or vibration.

For projects requiring durability, FEA is a must. Our team will give you a comprehensive analysis that points out design issues early, allowing for changes to happen in prototyping sooner rather than later, saving you time and costs in the long run.

Our FEA expertise extends to over 40 industries in companies across the United States.

Deliver A Valuable Product Every Time

Our team uses Finite Element Analysis to help you understand and predict how your product will react. You can use this data to:

- Remain competitive in your market

- Optimize design performance before prototyping

- Show proof of concept in your design

- Increase efficiency and eliminate failures

- Identify, stress, fatigue, temperature distribution and impact response

- Easily interpret and communicate this information to key members in your organization

- Much more...

Reduce the headaches in the engineering process and experience the Finite Engineering difference. Contact us today to learn how Finite Element Analysis will benefit your next project.

Read Our Engineering Case Studies To Learn How We Deliver For Clients Nationwide

Experience our real-world case studies to see how we put our expertise to work for clients, including finite element analysis (FEA), 3D modeling, new product development, production engineering, and much more.