What Is Reverse Engineering?

Learn Why Manufacturers and Engineers Seek Reverse Engineering Services

Reverse engineering is the process of understanding how a product was created, down to the most granular level. Engineers who provide reverse engineering services know that a component is more than the sum of its parts; it is also the labor and engineering expertise that went into its creation, and even the conditions it experiences while in use.

A reverse engineering team can help you understand a component or piece of equipment that will help you advance your business goals. Keep reading to discover why businesses seek out this service, what steps reverse engineering entails, and how to differentiate a superior reverse engineering team from the rest.

Why Reverse Engineering Matters For Many Businesses

Businesses require reverse engineering services for many reasons, including:

- A desire to recreate a part because there is no mold.

- The need for technical documentation for a part, when none exists.

- Demand for a specific part that is no longer available in a supplier’s inventory.

- The necessity of market research to understand how a component was made.

Understand the Steps Of a Rigorous Reverse Engineering Process

For manufactured components, there are several steps that an engineer must take to ensure effective reverse engineering.

- Investigation: Reverse engineering begins with a discovery process, so that engineers can best understand how a component is integrated into a larger system. Inquiring about a product’s purpose and function helps engineers understand the “why” behind the product they are reverse engineering.

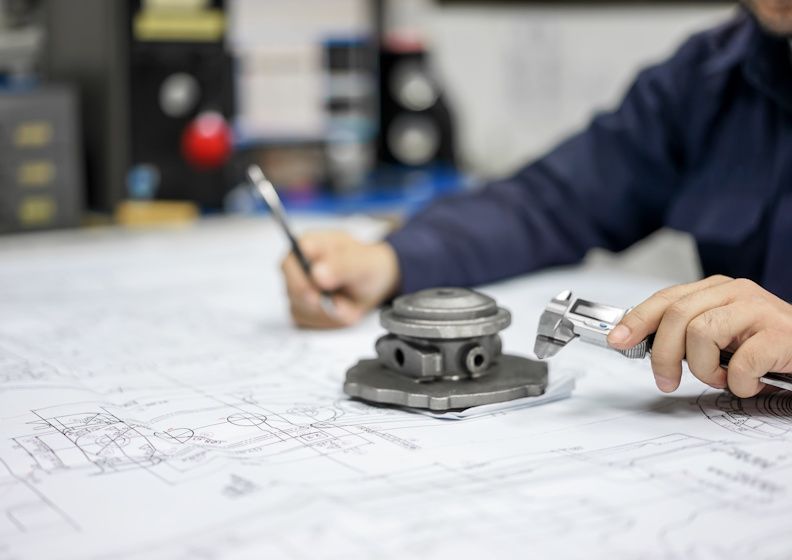

- Measurements: Engineers take measurements with calipers or create 3-D models of the product through light detection and ranging (LiDAR) equipment, or photogrammetry.

- Details and tolerances: Reverse engineering services include determining tolerances and features that play a role in how the component functions.

- Accounting for variation: Differences between how the component was manufactured and how it appears now are critical to accurate reverse engineering. When applicable, a reverse engineer will account for wear and tear, environment, or damage.

- Analyze materials and function: It is important for engineers to understand what materials were used to build a product, which can be accomplished by additional analysis, such as metallurgic analysis. Reverse engineers also seek to learn how the part operates within a larger system and how it affects operation. Engineers may consider techniques such as finite element analysis to understand the load or stress a product endures in the field.

- Modeling the product: The engineering team will create a 3-D model of the original product and complete the remainder of the process of product development, including analysis, validation, and technical documentation to ensure that it is ready for use.

What Differentiates One Reverse Engineering Service From Another?

On the surface, reverse engineering may be as simple as following the aforementioned process. But the process itself requires a high level of skill, experience, and critical thinking to properly execute each of its techniques with precision.

Leading reverse engineering teams can provide more than a recreation of the product; these teams can optimize the product so it performs better than before. In addition, they can provide benefits that other teams may not, including:

- Exceptionally detailed technical documentation.

- Protected servers to safeguard the details about your proprietary components.

- 3-D models of your 2-D drawings or molds.

- 3-D model files that can be used to program machining and milling equipment.

If you require reverse engineering services for a particular industry, you may consider seeking out an engineering team that specializes in that area. To vet an engineering service, ask about their experience with new product development for your industry, whether you’re in energy and mining, industrial manufacturing, waste and refuse, construction equipment, or any other specialized industry that depends on physical components.

A Reverse Engineering Team Can Provide Resources When You’re Tied Up With Other Priorities

Reverse engineering requires resources that your business may not currently have. Your engineering team may be tied up with client-facing needs, even when reverse engineering services would be beneficial to complete key tasks.

Therefore, many manufacturers and engineers lean on engineering consulting for reverse engineering services. A team specifically focused on your reverse engineering project is a far superior choice, as opposed to letting these projects go by the wayside or choosing an unproven engineer to help.

A new set of eyes on your project can reveal new solutions, opportunities, and optimizations that can benefit your business. By selecting dedicated reverse engineering services, you can experience a reduced project timeline and, most importantly, an effective product you can rely on moving forward.

Case Studies

Finite Engineering Warms Up the Railroad Industry

MOW Equipment Solutions, Inc., based out of Lenexa, Kansas, specializes in railroad maintenance equipment. MOW stands for Maintenance of Way, which includes a wide variety of parts and machines designed specifically for railroad repairs, upgrades and maintenance.

Finite Engineering’s Expertise Speeds Up a Project Timeline for Surgical Robots

Stereotaxis is a St. Louis-based company that uses magnetic fields to guide magnetic tips in medical equipment, such as in catheters and guidewires. The company’s products are diverse and consist not only of the large system that is external to the patient, but also the opposite end of the spectrum, the devices that go inside the body.

Breaking Ground

Trying to finish a project without an expert engineering team can be a real drag. That’s what Arizona-based Elite Equipment was finding as they tried to develop a new product, an arena drag that would till and smooth the surface inside large horse show arenas. The owner of Elite Equipment, Jesse Boyd, constructs high-end horse arenas. Boyd believed that he could design an arena drag that was a significant improvement over the current models available.

On Time, Within Budget

Lenexa Manufacturing Company in Lenexa, Kansas, is owned by a family that has been baking for over a century. This passion for baking equips them to help bakers automate their slicing and bagging with high-tech equipment, improving efficiency and line speed to bag one loaf every second.

Sidestepping a Critical Error

ZGC ran into a problem when one of their two CBUs was installed. It had a vibration issue and over the last few years this issue has been destroying the machine foundations. For a machine that is the width of two Mississippi barges, this was a significant challenge. The problem was in the design, but ZGC needed a way to fix it.

Stamp of Approval

As a manufacturer-supported supplier of steel shipping racks across a variety of industries since 2000, SPS Ideal Solutions, Inc. creates custom designs to the specifications of each client. Some of the key industries they support are flexible packaging film, film for the tape industry, steel, aluminum coils, fabricated components, vehicle panels and finished engines.

When cost and schedules matter to your project.

Finite Engineering is here to help.

Helpful Resources

Contact Us

Fill out the form below and we will contact you.

Footer Form

We will get back to you as soon as possible.

Please try again later.