What Do Product Development Engineering Teams Offer Industries With Heavy Equipment and Machinery Needs?

The Rationale Behind Selecting a Trusted Engineering Consultant

Companies in industries with heavy equipment and machinery depend on them for daily operations. When these products fail to perform as expected, a challenge can quickly snowball into a crisis.

These companies must rely on the manufacturers who build this equipment to help them avoid small and large-scale failures. However, many manufacturers require engineering experience that goes beyond their capabilities. For this kind of specialized support, manufacturers look to engineering teams with product development expertise.

Yet preventative measures to avoid failure are only a fraction of what product development engineering teams can provide. New needs will arise to help companies push their capabilities further. Industry shifts will require innovation to help these businesses remain competitive.

Select a team for new product development engineering with strategic, agile capabilities that can bring you success today, help you evolve for the future, and meet demand wherever you find it.

The Value Every Product Development Engineering Team Should Provide

The waste and refuse industry depends on high–performing conveyors, shredders, loaders, and compactors. The mining and energy industry needs conveyors, processing equipment, excavators, haulers, and more to complete routine processes.

Whether your focus is on these industries, construction, industrial manufacturing, maintenance of way, agriculture, or the many other markets that depend on expertly engineered heavy equipment and machinery, finding a valuable engineering team with highly effective new product development processes is key.

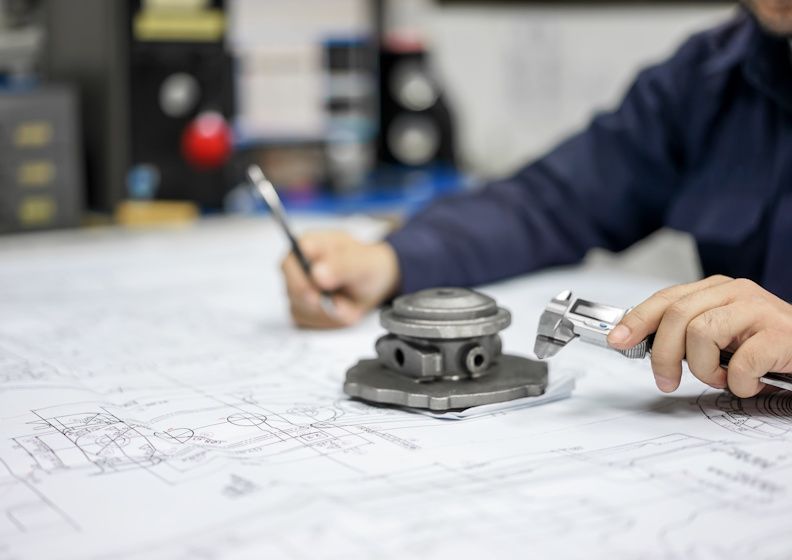

When tapping a product development engineering team to design your most important assets, focus on these four characteristics:

- Risk reduction: A trusted product development engineer should be able to limit your risk exposure through a rigorous approach to concepting, modeling, analysis, documentation, and more. Throughout the new product development lifecycle, an engineer narrows their focus down to a solution that will yield results by helping you define your challenge, asking the right questions, exploring solutions, and landing on a feasible product.

- Resource management: Although prototyping is, by nature, an iterative process, virtual prototyping and 3D modeling can reduce costs and bottlenecks.

- Analysis and optimization: Select a team with experience in finite element analysis (FEA) for a comprehensive determination of your product’s effectiveness in the field under stress.

- A seamless workflow: Engineers experienced with the new product development process provide even more than a high level of knowledge in their field. To best serve their clients, they implement an organized project management structure to keep all parties informed about the project lifecycle and aim for on-time delivery. Engineers begin to feel like a part of your team, not just an outside consulting firm. They strive for collaboration, ease of integration, and smooth project phases.

- A foundational engineering philosophy: No matter how robust your chosen team may be, their product development approach should be informed by a design philosophy that targets your specific engineering problem, reduces extraneous project phases, limits unnecessary costs, and enhances the efficacy of your equipment. One such philosophy is a “first principles” approach.

What Is a “First Principles” Approach to Product Development Engineering?

When your business has an urgent need for new or improved equipment, machinery, and components to continue strengthening your business, seeking a product development engineer with a “first principles” design philosophy gives you a marketplace advantage.

The ancient Greek philosophers had a word for the starting point or initial concept from which all other knowledge flows: arche. One of Aristotle’s fundamental ideas about how we perceive the world, archai are the concepts or facts from which the next set of facts are derived. In the scientific world, this Aristotelian approach, now referred to as first principles thinking, helps us make deductions based on shared underlying concepts.

The value for a product development engineers’ client is clear: when an engineer establishes a clear, unshakable understanding of the basic physics of a design, alongside an agreed-upon sense of what problem needs to be solved, they can introduce a solution that is exclusively informed by these facts. Engineers who operate by this philosophy strive to simplify a path to a product’s success.

The benefits of a first principle design philosophy include:

- Fresh perspectives on how to solve an engineering challenge.

- Efficient and creative problem-solving.

- Resource allocation focused on a solution, not unsuccessful attempts.

- The ability to quickly eliminate irrelevant design concepts.

- Scalability based on the fundamental effectiveness of the initial design.

Engineers without a new product development strategy defined by first principles may end up over-engineering, expending resources on superfluous iterative designs, or simply creating a final product that doesn’t obey its inherent physics and fails to perform in the field.

Whether you require new product development for construction products, energy and mining, waste and refuse, industrial manufacturing, or any industry that requires heavy equipment, machinery, and components, your advantage lies in selecting an engineering team with a new product development process that front-loads their work with first principles.

One Key Characteristic Of a Strong Product Development Engineering Team

First principles, when applied alongside experience in concepting, prototyping, 3D modeling, analysis, optimization, and more, position you for success in your field - affordably, quickly, and sustainably.

Ultimately, this means that first principles puts more than just your concept first - this approach puts the client first. Clients hire product development engineers for their expertise with the new product development process, but if that isn’t implemented with their most pressing needs in mind, the project is flawed, no matter how well-engineered it may be.

Whether you require engineering for new product development for construction products, energy and mining, waste and refuse, industrial manufacturing, or any heavy-equipment-centered industry, seek out engineers who are as committed to your mission as you are.