What Is Product Development Engineering?

This Process Offers Significant Value For the Manufacturing Industry

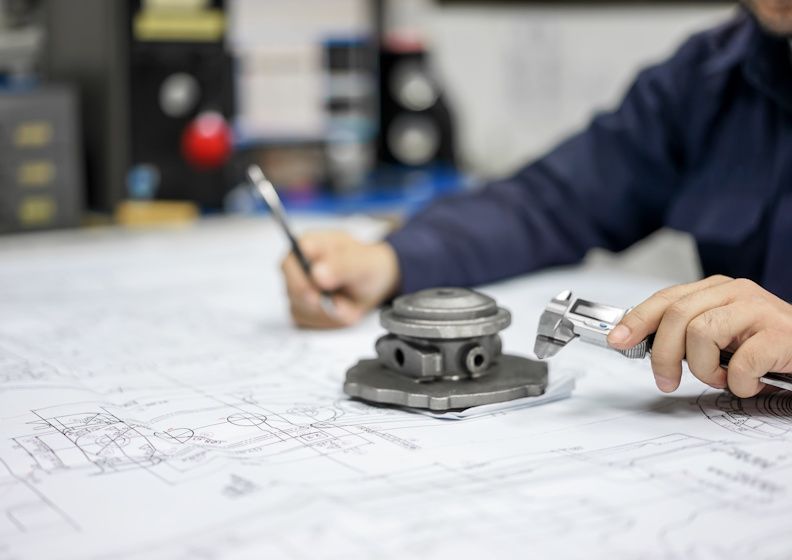

Product development engineering is driven by a desire to create solutions for design challenges. A dynamic and comprehensive process, this form of engineering requires expertise every step of the way and superior project management procedures, so that each individual step in the development process adds value to the next.

A standard new product development engineering lifecycle may include these phases:

- Determining requirements

- Product concepting

- Product research

- Sourcing

- Cost analysis

- Design

- Drawings and modeling.

- Material selection.

- Analysis and validation.

- Technical documentation.

- Shipping and transport configurations.

Each of these steps is an intensive product development engineering service in itself, demanding long-term experience and premium resources, such as the latest software, to ultimately ensure a product’s field readiness.

Some businesses have in-house engineering teams that can meet these standards. But not all are fortunate enough to have this resource at their disposal. Alternatively, a business can seek out an engineering consultant, but the team they choose must have a significant depth of knowledge and expertise. It takes a robust engineering team to shepherd a product through development, so it’s ready for operation.

The manufacturing industry recognizes the importance of strong product development partnerships. Manufacturers often hire engineering consultants who can provide the full range of services involved with product development engineering.

What the Manufacturing Industry Has Learned About Full-Service Product Development Engineering

It goes without saying that every manufacturing company wants to ensure that they are responsive to their customers. Along with delivering the products that the customer depends on, a manufacturing company thrives when it is able to help businesses expand their capabilities with new offerings, find new efficiencies for their processes, or deliver solutions when industry changes occur.

A manufacturing company’s responsiveness depends on its ability to provide new product development engineering, including designing, building, and validating products.

However, not all manufacturers have the resources to do so. Their engineering departments are frequently allocated elsewhere, even when they have the expertise to deliver comprehensive new product development engineering services. To solve this challenge, manufacturing companies understand the value of outside engineering consultants, who step in to tackle the product development process as needed.

4 Benefits Of a Product Development Engineering Consultant

Product development teams that support the manufacturing industry are useful for more than bridging a gap. Although an engineering consultant is primarily valuable when in-house engineers aren’t able to provide the amount of support they would prefer to give, a consulting team offers additional benefits:

- New perspectives: Bringing in a fresh set of eyes to consider an approach to product development engineering unlocks creativity and uncovers optimal solutions that may not have been previously considered. Tapping expertise to reveal new ideas is a hallmark of many successful businesses.

- Resource utilization: In-house engineers can return their attention to their typical priorities and focus more energy there, now that a consulting team has freed up their time.

- Code and compliance: Product development engineers also provide a depth of experience with code and compliance requirements for your market in the event that a new product represents unfamiliar territory.

- Risk reduction: Similarly, if your company is tasked with scaling an existing product or breaking new ground, a team that offers new product development engineering services protects your design from vulnerabilities during each project phase.

A Fifth Benefit Depends On the Engineering Team You Choose

Strong consulting teams deliver a fifth benefit that makes them desirable to certain businesses that are wary about bringing in outside services: they operate as an extension of the existing team.

Engineering consultants must seamlessly integrate with their partners as they provide services. A team that fully integrates itself can make a powerful contribution to a company that requires new product development engineering strategies and services:

- Collaboration: An exceptional consulting team listens. Businesses have a wealth of context and knowledge to share that is critical for finding the right solution.

- A customer-first approach: Without a commitment to serving their customers, the quality of their new product development engineering procedures may lack the necessary diligence required to create an effective product.

- Transparency: A business hiring an engineering consulting team deserves clear communication to ensure they’re meeting timelines and understanding expectations.

Working well with your team may be the most critical characteristic of any engineering consulting firm, as it ensures the other benefits these consultants bring to the table are fully realized.

When a consulting engineering firm

works authentically and meaningfully beside your existing team, their approaches, recommendations, and solutions feel like a collective win.