Leverage Our Approach to Reverse Engineering

Finite Engineering Demonstrates Our Commitment to Uncovering Unique Solutions

Finite Engineering’s reverse engineering services ensure that you can reach your next business goal with success. We’re prepared to deliver reverse engineering best practices when your team:

- No longer has access to a mold for a critical component.

- Requires documentation for a part that had no prior technical documents.

- Realizes that a part is no longer accessible for purchase.

- Wishes to conduct market research to evaluate the pros and cons of current approaches.

Known for our work in new product development, including mining and energy, industrial manufacturing, waste and refuse, construction equipment, and more, we solve design challenges, ensure products’ readiness for the marketplace, and hand them off to our clients with confidence. Our dedication to tackling engineering problems also equips us for the critical thinking and insight required to provide you with reverse engineering services.

Our reverse engineering company is ready to help you with your project. Contact us online or call (913) 681-8282 to get started today.

Technology We Use For Reverse Engineering Services

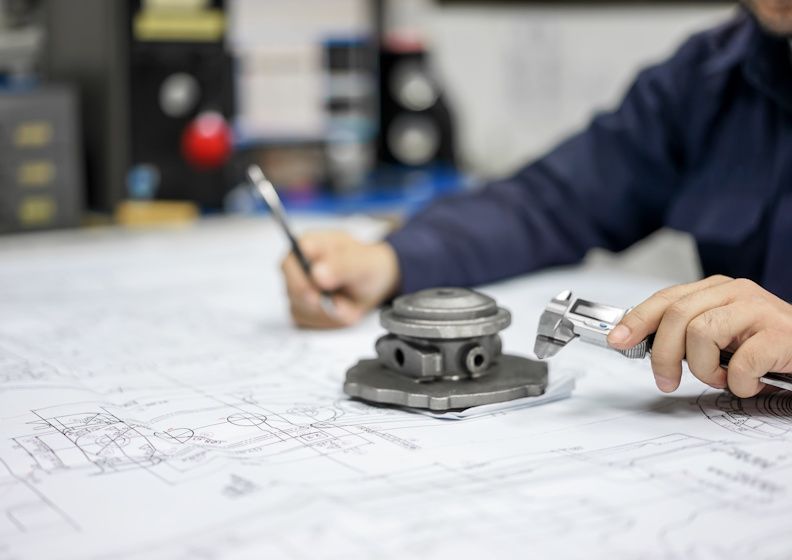

Finite Engineering provides expertise with the various technologies used today for reverse engineering solutions, including laser scanning with light detection and ranging equipment (LiDAR), photogrammetry (the use of photos to develop 3-D models), and traditional hand tools, like calipers.

In some cases, our clients who seek out our help have molds, 2-D drawings, documentation, and the physical parts they’re trying to engineer. However, these materials don’t necessarily allow businesses to continue manufacturing these parts with the technology they currently use.

We can bring your product into the 3-D world with the latest technology to provide you the most accurate documentation of what you’re building. Our fully-dimensional 3-D model can then be programmed into your manufacturing equipment, such as CNCs or mills, to effectively produce your product.

We’re ready to help you with our software and technology. Contact Finite Engineering now.

A Willingness to Explore the Best Resolution to Your Reverse Engineering Challenge

Reverse engineering is more than the deconstruction of a product to determine how it was designed. Finite Engineering’s approach views this service from a larger context.

Our best practices for reverse engineering include:

- An investigation into the part’s purpose, function, and its place in a system.

- Our validation expertise, including finite element analysis, which allows us to quickly recognize deficiencies in a product and make recommendations for improvement.

- Carefully accounting for variations in the product due to wear, damage, and environmental effects.

- Gathering an understanding of the product’s original tolerance to ensure it functions as intended. We can even optimize a product for a tighter tolerance to enhance its performance.

Learning From a Competitor’s Approach

Although we never replicate your competitors’ products, we find value in using reverse engineering to better understand how a component works. Our reverse engineering services allow you to gain insight into specific products, so you can continue innovating to keep in lock-step with your competition.

Protecting Your Work

When we help you reverse engineer your proprietary products, we always ensure that your information, including documentation, drawings, and more, are completely secure. We are a U.S.-based company operating on US-based servers to offer you the confidence and protection your products deserve.

The Importance of Technical Documentation

It is not uncommon for companies to identify a need for a product, then head into the shop and build it. These products may last for many years, long after personnel and their institutional knowledge has left the business.

But when you hope to recreate that product, there’s little-to-no documentation available. With our reverse engineering services, you can use your product as intended and obtain highly detailed technical documentation for future reference.

Similarly, a manufacturing company may have designed a product and prepared documentation, but, after an acquisition by another firm, the documentation goes missing or needs to be brought up to new company standards and branding. When your customer base begins asking for that documentation, our team can step in and provide best practices for reverse engineering to deliver the necessary information.

Let us help you with reverse engineering and technical documentation to resolve your engineering challenges. Contact us online to learn more about us.

What Isn’t Production to You Is Production to Us

The value of an engineering consulting firm is our commitment to a seamless integration with your current engineering team. Many times, your engineering personnel are tied up with critical output for your business’ bottom line and don’t have the time or resources to tackle a reverse engineering project. Shifting your in-house team’s priorities during a busy operational season may be cost- and time-prohibitive. Your challenge is our priority. The engineering bottlenecks that may take up too much of your time are our specialty.

Connect With Finite Engineering For Superior Reverse Engineering Services

Whether you require reverse engineering best practices, product development, or any of our solutions-driven services, we offer the same committed spirit.

We also offer new product development services that are just as comprehensive and innovative. We help manufacturers build the products they require by working as an extension of their engineering team. Finite Engineering offers new product development for mining and energy, industrial manufacturing, waste and refuse, construction equipment, and other industries that require heavy equipment and machinery.

Contact us online or call (913) 681-8282 to discuss your project.

Case Studies

Finite Engineering Warms Up the Railroad Industry

MOW Equipment Solutions, Inc., based out of Lenexa, Kansas, specializes in railroad maintenance equipment. MOW stands for Maintenance of Way, which includes a wide variety of parts and machines designed specifically for railroad repairs, upgrades and maintenance.

Finite Engineering’s Expertise Speeds Up a Project Timeline for Surgical Robots

Stereotaxis is a St. Louis-based company that uses magnetic fields to guide magnetic tips in medical equipment, such as in catheters and guidewires. The company’s products are diverse and consist not only of the large system that is external to the patient, but also the opposite end of the spectrum, the devices that go inside the body.

Breaking Ground

Trying to finish a project without an expert engineering team can be a real drag. That’s what Arizona-based Elite Equipment was finding as they tried to develop a new product, an arena drag that would till and smooth the surface inside large horse show arenas. The owner of Elite Equipment, Jesse Boyd, constructs high-end horse arenas. Boyd believed that he could design an arena drag that was a significant improvement over the current models available.

On Time, Within Budget

Lenexa Manufacturing Company in Lenexa, Kansas, is owned by a family that has been baking for over a century. This passion for baking equips them to help bakers automate their slicing and bagging with high-tech equipment, improving efficiency and line speed to bag one loaf every second.

Sidestepping a Critical Error

ZGC ran into a problem when one of their two CBUs was installed. It had a vibration issue and over the last few years this issue has been destroying the machine foundations. For a machine that is the width of two Mississippi barges, this was a significant challenge. The problem was in the design, but ZGC needed a way to fix it.

Stamp of Approval

As a manufacturer-supported supplier of steel shipping racks across a variety of industries since 2000, SPS Ideal Solutions, Inc. creates custom designs to the specifications of each client. Some of the key industries they support are flexible packaging film, film for the tape industry, steel, aluminum coils, fabricated components, vehicle panels and finished engines.

When cost and schedules matter to your project.

Finite Engineering is here to help.

Helpful Resources

Contact Us

Fill out the form below and we will contact you.

Footer Form

We will get back to you as soon as possible.

Please try again later.