How Finite Element Analysis Offers Solutions

How Finite Element Analysis Offers Solutions

Before legendary inventor Nikola Tesla started any new project, he always took time to first work his plans out extensively in his mind.

"When I get an idea," he would say, "I start right away to build it up in my mind. I change the structure, I make improvements, I experiment, I run the device in my mind." In taking part in a deep thought experiment, Nikola Tesla was doing something very similar to what Finite Element Analysis (FEA) does today.

He was testing the limits of his plans, looking for problem areas, and hoping to solve them before they even became an issue.

How Finite Element Analysis Works

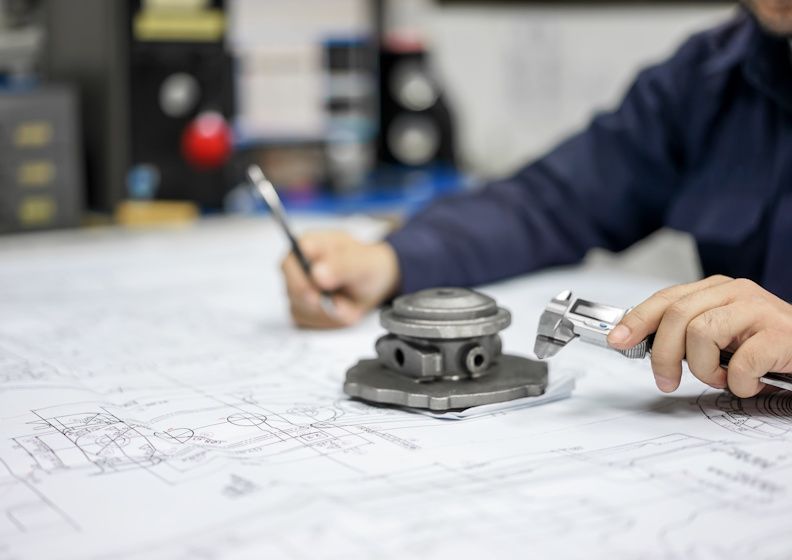

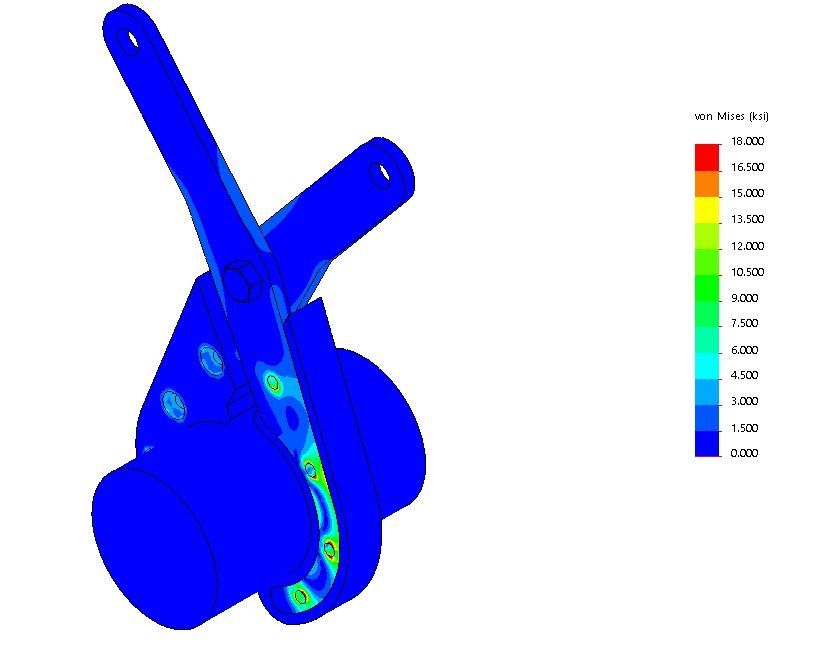

Finite element analysis is a useful tool for product design and failure analysis; it is widely available and can provide useful insight into complex problems. (ScienceDirect) By far the most widely used and versatile technique for simulating deformable solids, FEA is a simulation that employs mathematical techniques to run complex structural analysis on your product via a suite of software.

Through this process, you're able to identify any potential problems, weaknesses, and areas of concern and address them before you even make a physical prototype.

With FEA, our engineers here at Finite Engineering are able to perform product quality analytics that include:

- Linear

- Non-linear

- Vibration

- Buckling

- Impact

- And more