Mechanical Engineering vs. Production Engineering: What’s the Difference?

Mechanical Engineering vs. Production Engineering: What’s the Difference?

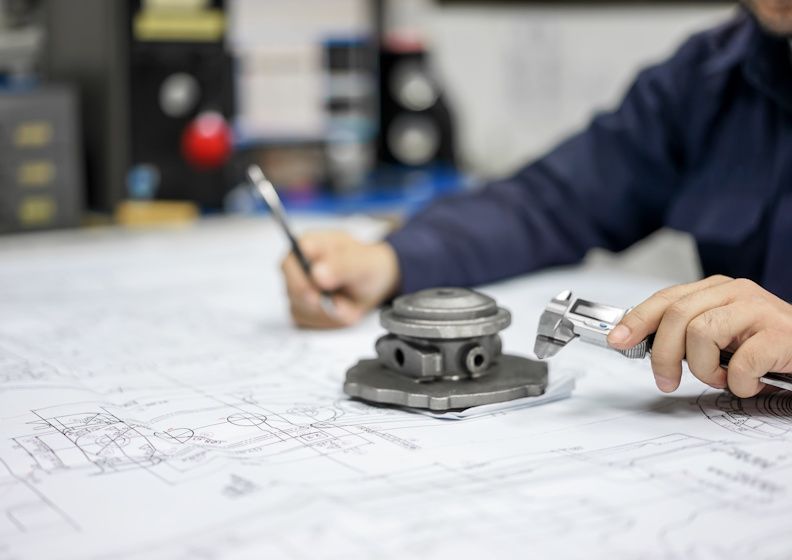

Mechanical engineering and industrial sometimes referred to as “production” engineering are both integral parts of the engineering process. Understanding the difference between these two professions is an important step towards understanding how to effectively manage your engineering project from design to completion.

In this article, we will explore what each profession does, their respective roles in the project-management life cycle and how they interact with one another throughout the process.

What is Mechanical Engineering?

The overarching role of a mechanical engineer is to create, design and analyze machines. This can be everything from the tiny components that make up your cell phone or laptop, to something as large as an engine for a car or airplane.

Mechanical engineers develop solutions like components for transportation devices such as airplanes and motorcycles, heating ventilation and air-conditioning systems, robots used in manufacturing, medical instruments like MRIs, amusement park rides, food production equipment, heavy machinery and more.

They also work on solutions to problems in energy production, agricultural operations, or even medical devices. As an example of how broad this profession can be, some universities offer degrees related to nanotechnology where students studying at the graduate level focus specifically on micro-machines smaller than 100 nanometers!

The role of a mechanical engineer often begins early in product development when they might help design prototypes before transitioning into full scale manufacturing processes. This type of thinking requires specific attention to detail and creativity, as there may not be any existing products to build from or reverse engineer.

The Role of a Mechanical Engineer:

Mechanical engineers usually work with other production professionals such as manufacturing, electrical engineering or tool designers to produce the best results for the end product.

During prototyping they must pay close attention to detail while also considering how each aspect of the project will contribute to its overall success. This type of engineer is not only highly skilled at math and science but often possesses strong problem solving skills since problems may arise throughout every step of the engineering process.

This type of individual employs very careful analysis before determining how to move forward with a solution.

What is Production Engineering?

Production engineering is also referred to as manufacturing or industrial engineering. This profession works in tandem with mechanical engineers and other team members during the design process, but it ultimately focuses on implementing what has been designed by others (the mechanical engineer) into a final product that will be used by consumers.

Production engineering operates throughout the entire project-management life cycle. From designing products down to minute details such as size and shape; helping to determine how products should actually be made (through various workflows); and monitoring production for quality control purposes. All of this helps to ensure the end product meets specifications outlined in blueprints created earlier in the development process.

The Role of a Production Engineer:

Production engineering is tasked with laying out the guidelines for how to actually assemble products by creating workflows that are efficient and cost effective.

Once blueprints have been completed, production engineers coordinate with everyone involved in making the product (such as manufacturing) so they can all begin working toward the same goal - producing an exceptional end result. In addition to overseeing workflows, production engineers also coordinate the creation of equipment that will be used during manufacturing processes.

They will often consult with other departments like purchasing or logistics in order to determine which machines and tools should be purchased for optimal results.

The Similarities Between the Two Engineers:

Production engineering and mechanical engineering work together during the entire engineering design process. While production engineers focus on implementing what has been designed by mechanical engineers into a final product, they must also fulfill many of the same tasks as other types of engineers like performing mathematical calculations and creating the blueprints for production floor layouts.

Both engineers are skilled at predicting how complex problems can be resolved using simple solutions derived from years of experience working with machines. Both professions require math skills and problem solving abilities since there is always some sort of obstacle that arises throughout any project-management life cycle.

The information gathered in solving the various obstacles is then used by marketing teams or other professionals like production managers in order to make final decisions about which product should go into mass-production.

In Conclusion

The relationship between production engineering and mechanical engineering is a two-way street. Mechanical engineers develop the product while production engineers determine how to turn that design into an end product using their own set of tools, blueprints, equipment and expertise in working with machines.

Both have important roles during this process which are better understood when thought about together rather than separately. Finite Engineering has over 35 highly experienced engineers ready to help your team accomplish both mechanical and production engineering demand. If you have any questions about the engineering process or to get a better understanding, please contact us.