Meet Finite Engineering's Project Engineer, Bill Baker

Like many of the fine engineers across the country and especially in Missouri, Bill Baker is a product of the engineering school in Rolla – Missouri University of Science and Technology, also known as Missouri S&T.

Baker has two years under his belt at Finite Engineering, where he is a Project Engineer, but his interest in the craft began when he was a young farm boy.

“I was raised on a farm and was exposed to mechanical things,” he said, adding that he had a habit of taking those things apart and putting them back together. “I was the mechanically inclined person in my family.”

To this day, Baker is a self-proclaimed “tinkerer” and has a project car in his garage, but also does all the maintenance on the family automobiles because, as he says, “It’s in my blood.”

Finding His Path

Like most youngsters, Baker questioned where he wanted to go in life and originally set his sights on a drafting career while in high school. But curiosity led him to a question: who tells the drafting professional what to draw?

The instructor told him that it was an engineer who gave the instructions for drafting, Baker recalled. “So, I decided I was going to be an engineer.”

The next logical step following high school graduation was the engineering program in Rolla, which is renowned across the region for producing well-prepared engineers. Baker applied, was accepted and “The rest is history,” said Baker.

Leading Projects

Baker’s story is similar to that of others at Finite Engineering who have experience working at large engineering firms. He said he was never comfortable in a corporate setting, and the internal tension created an atmosphere that led him to seek out other opportunities.

He landed at Finite Engineering two years ago and has felt right at home in the small firm. From getting to know the owner, Jasen Sappenfield, on a personal level to working closely with customers, it’s been an excellent fit for him.

“I get to wear many hats and take on many challenges,” he said. “There’s always something new coming around the corner, such a variety of projects where I get to work closely with customers and help them solve problems.”

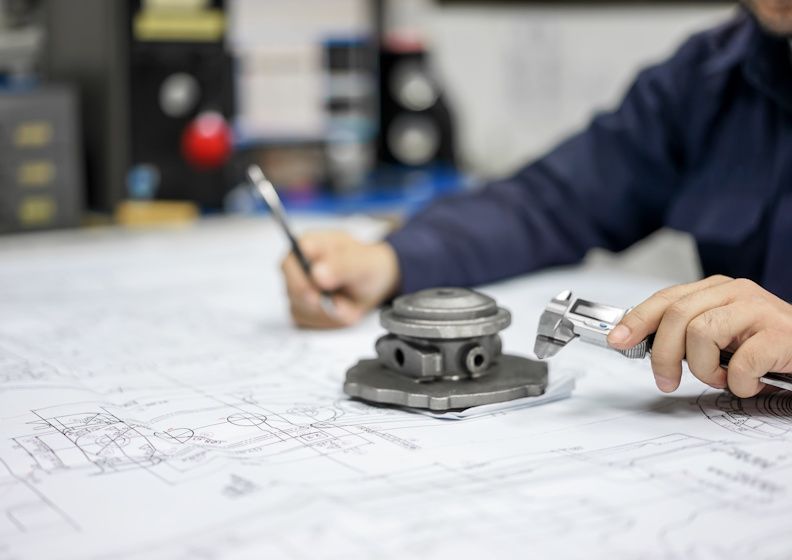

Managing anywhere from five to 10 projects at a time, Baker’s role as troubleshooter suits his talents perfectly. But he’s also constantly working on new solutions, concepts or technologies, searching for multi-functional solutions from a mechanic’s point of view.

“Some of the projects I oversee and manage,” he said, “but on others, I get right down in the middle of it, so it’s kind of nice.”