What Is the Purpose Of Finite Element Analysis Engineering?

Discover How FEA Engineering Services Solve Your Engineering Challenges

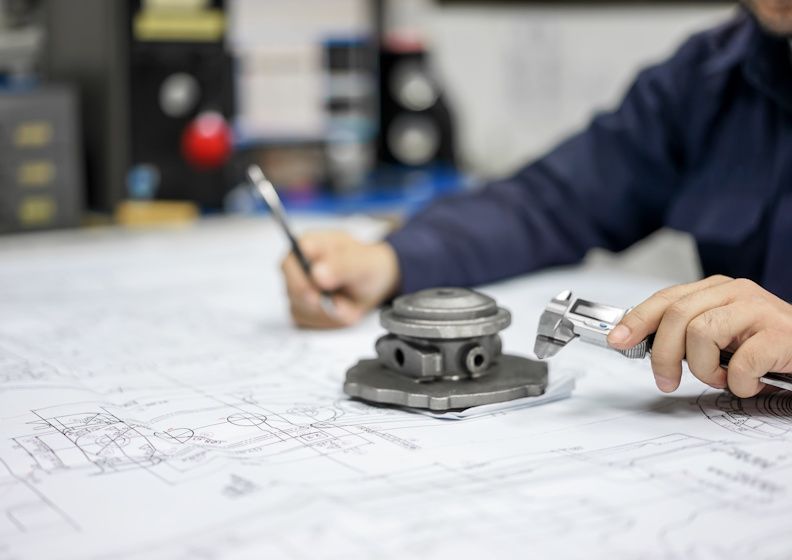

Finite element analysis (FEA) is an essential and enduring tool for industries where machine failure isn’t an option. The ability to analyze the performance of your equipment and machinery under stress has globally transformed the quality of manufacturing processes. Perhaps most importantly, FEA provides necessary reassurance for businesses, knowing they can continue to trust the assets that help them deliver excellent services and products.

Finite element analysis, however, isn’t a static resource. From its infancy in lecture halls and academic papers nearly a century ago, finite element analysis has evolved alongside the exponential growth of technology that characterizes our lives today.

FEA engineering is as useful now in the digital age as it was when it was first conceived. This process will continue to demonstrate its value as new product development for agriculture, construction, transportation, mining, and more are required in a marketplace defined by innovation.

The History Of Finite Element Analysis Engineering

The finite element method (FEM), which is the approach used for conducting FEA engineering, was initially conceived as a means to study structural analysis and mechanics (e.g., analyzing the behavior of a cylinder under torsion, or stress). In the early 1940s, two mathematicians, Richard Courant, who expatriated from Germany to the U.S., and Alexander Henrikoff, a Russian-Canadian, developed an initial solution for such engineering problems. Their work became the bedrock upon which FEA is founded: the discretization of an object into smaller elements.

By the 1950s, Ray Clough, an American professor at UC Berkeley, teamed up with John Turner, head of engineering for Boeing, to apply the kernel of Courant and Henrikoff’s work with discretization. To study how aircraft perform under various conditions, Clough and Turner developed the direct stiffness method, which includes discretizing “elements” of a material object, which are all interconnected at nodes.

During this method, nodes are articulated as equations and then mapped as a matrix, or a mesh that represents the whole structure. Each node’s and the global structure’s six degrees of freedom (DOF) are calculated to determine how the individual elements and the global structure can potentially be displaced or deformed. Ultimately, boundary conditions, such as force, are iteratively applied to the matrix of equations to discover how stress and strains put on the structure affect its operation.

The continued contributions of several other gifted scientists, including John Argyris and Ed Wilson, created the groundwork for how we use finite element analysis engineering today, including the computerized, two-dimensional, semi-automatic processes for applying loads that emerged alongside computer science in the 1960s.

Much like other technological breakthroughs of the late 20th century, the journey of finite element analysis has mirrored the growth of the software industry. FEA’s continued growth is now a matter of improving FEA engineering software for faster, more complex capability and an exceptional user experience.

How Is FEA Used Today?

The purpose of finite element analysis services today is very similar to what was intended at its inception: to determine how certain parameters affect a given structure. FEA engineers can provide several forms of analysis for a particular component or piece of equipment, depending on its particular requirements in the field. These analyses include:

- Fatigue analysis

- Linear and nonlinear analysis

- Explicit analysis

- Buckling analysis

- Dynamic analysis

- Vibration analysis

What Software Is Used For Finite Element Analysis Engineering?

Today, the leading tools for finite element analysis services include these widely used programs:

- Employable at any stage in the FEA process, Autodesk Inventor Nastran and SolidWorks Simulation allow engineers to input native CAD files into these systems to perform seamless pre-processing, analysis, and post-processing functionality.

- Abaqus, a Simulia product, provides high-end, complex analysis, which takes factors such as time dependency, multiprocess forming, and large deflection theory into account to deliver an accurate assessment of structures with nonlinear relationships between force and deformation.

New FEA engineering software includes:

- Fusion 360, a cloud-based FEA product.

- OnShape, which pulls together many aspects of the FEA workflow and project management cycle.

As FEA services continue to expand their capabilities, it is important to remember that, much like other forms of technology, these tools are only as effective as their users. Keep reading to find out how to choose an experienced FEA team, whether you want to analyze a product that is currently failing in the field or you want FEA support as you begin new product development for industries such as agriculture, construction, transportation, mining, and more.

Finding Your Finite Element Analysis Engineering Team

When looking for a FEA engineer to help you analyze your machinery or equipment and make assumptions about how it will perform under particular forms of stress, you must consider their depth of experience.

Look for a team with expertise that has grown alongside FEA engineering’s many changes over the years. For instance, a team that has learned and mastered a wide variety of software over time has the flexibility and versatility to solve problems with the benefit of experience. They know the right technology and resources to leverage for the variety of engineering challenges that industries face.

The proliferation of finite engineering software has made FEA tools more accessible. What used to be a process reserved for high-powered computers in well-funded engineering laboratories is now a downloadable software package.

However, this accessibility shouldn’t necessarily be mistaken for ease of use. There is an art and science to FEA that are best handled by a team that can ensure an accurate analysis. After all, your investment in your business’ critical assets - your equipment and machinery - determine your marketplace success.

Learn more about how to identify excellence when seeking finite element analysis services.